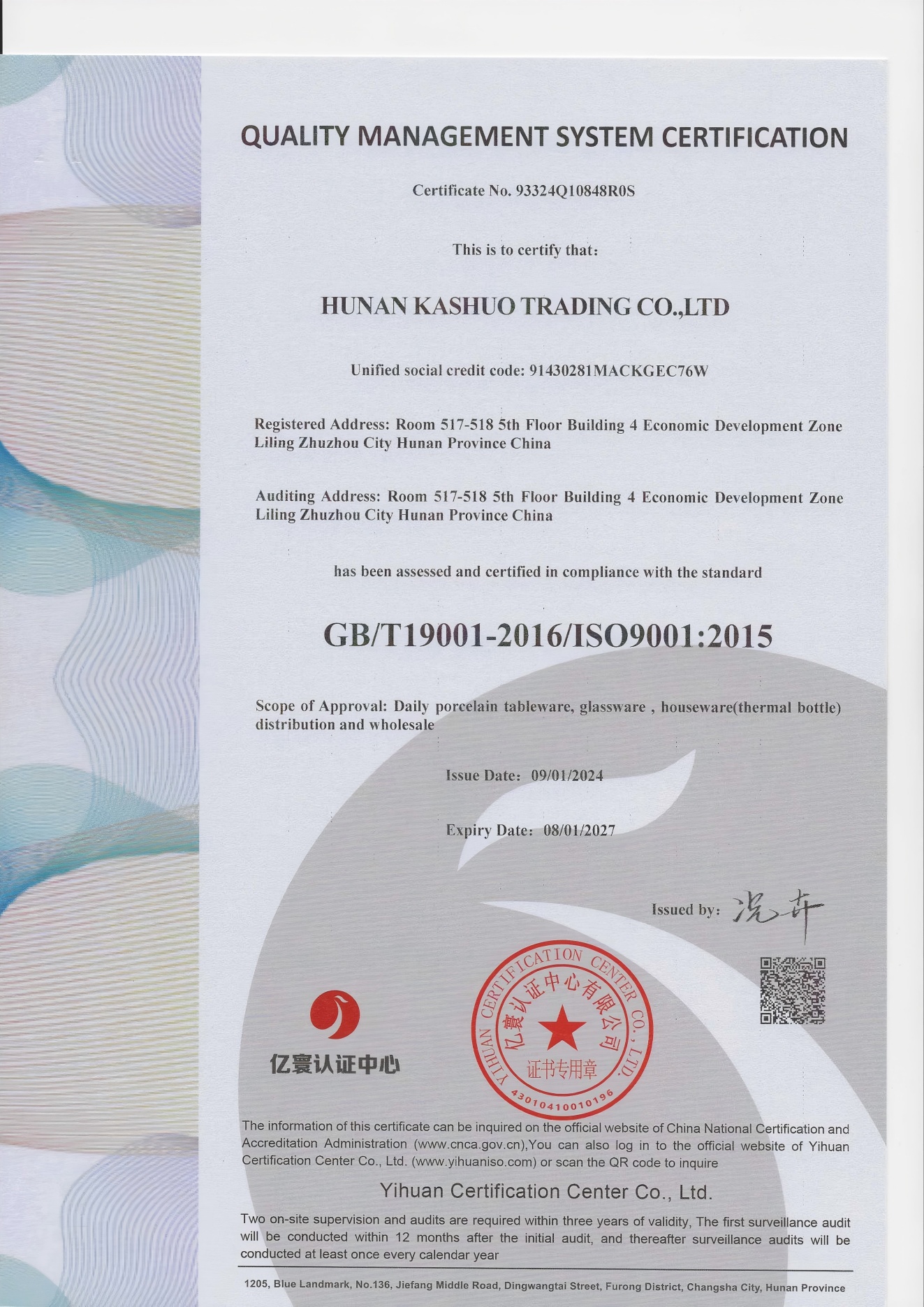

STORIWARE Ceramics,with 15 years of establishment, is an inheritor of Liling underglaze color intangible cultural heritage. For years, we have focused on ceramic R&D and production, committed to transforming the millennium-old ceramic wisdom into modern and international tableware solutions. Relying on a 20,000-square-meter intelligent production base, we integrate traditional craftsmanship with modern technology, and have built 15 full-process production lines (including 2 exclusive lines for intangible cultural heritage underglaze color). With a monthly production capacity of 5 million pieces, our services cover more than 50 countries and regions worldwide, serving international benchmark enterprises such as French Michelin restaurants, American Target supermarkets, and Japanese home brands.

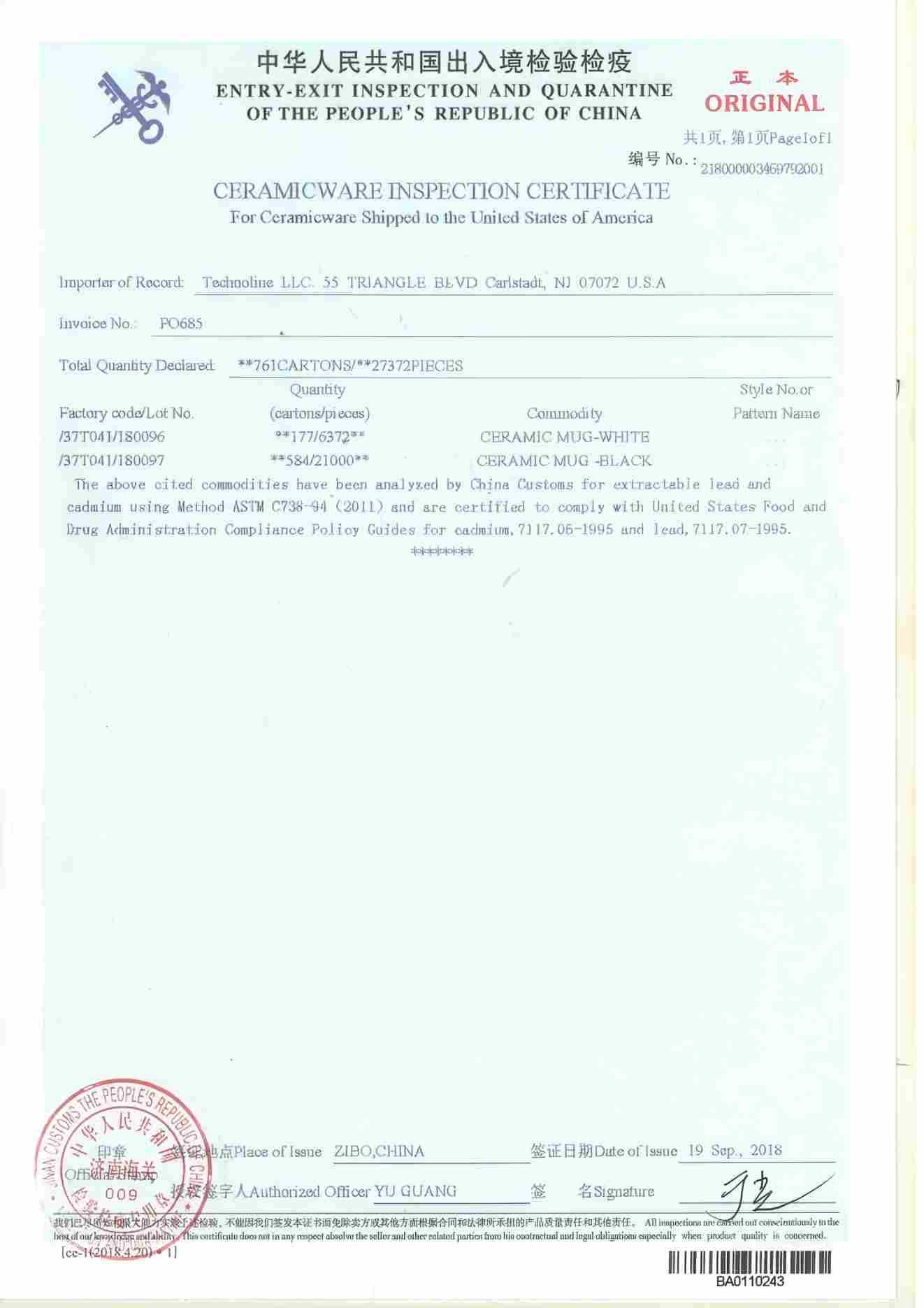

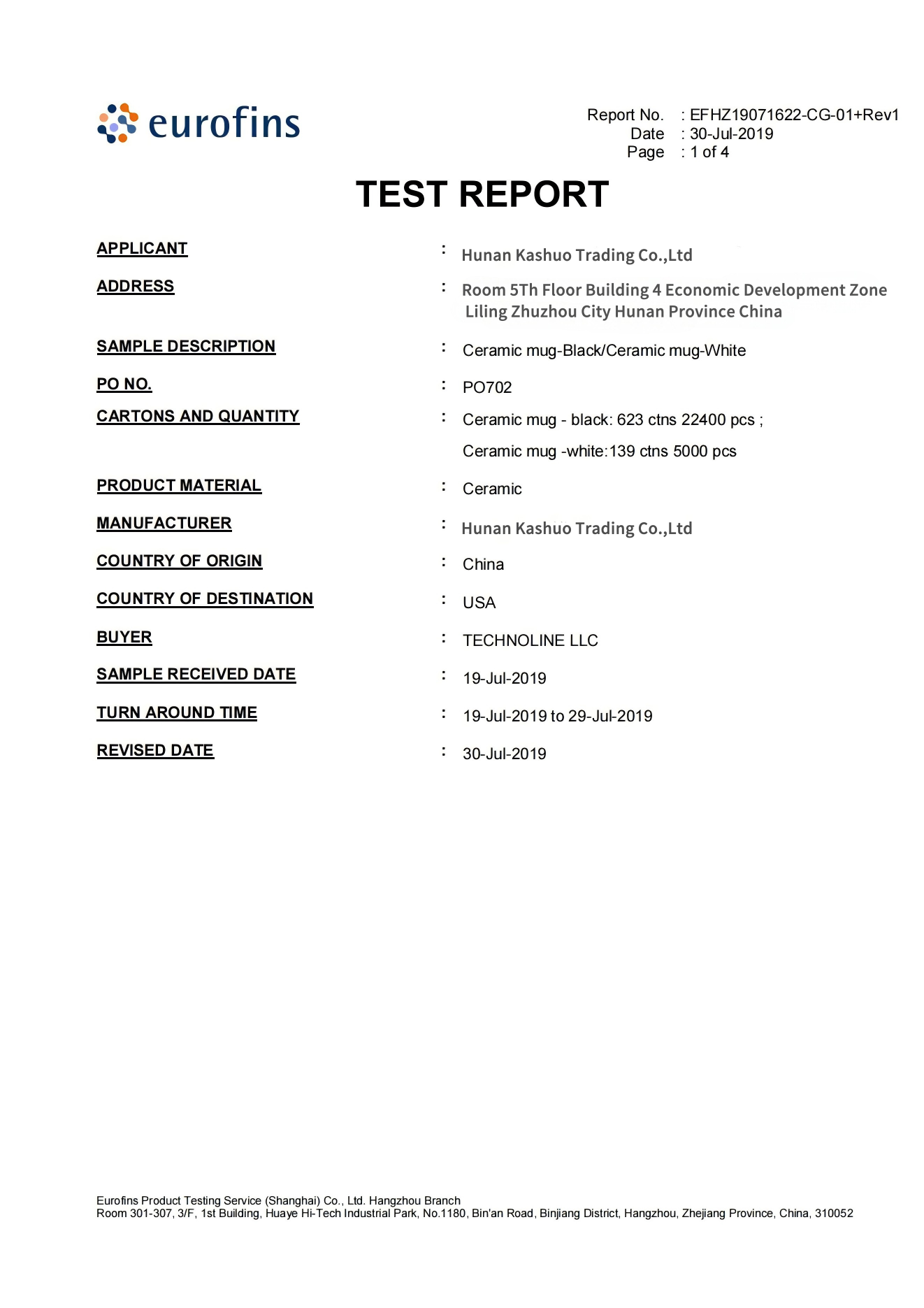

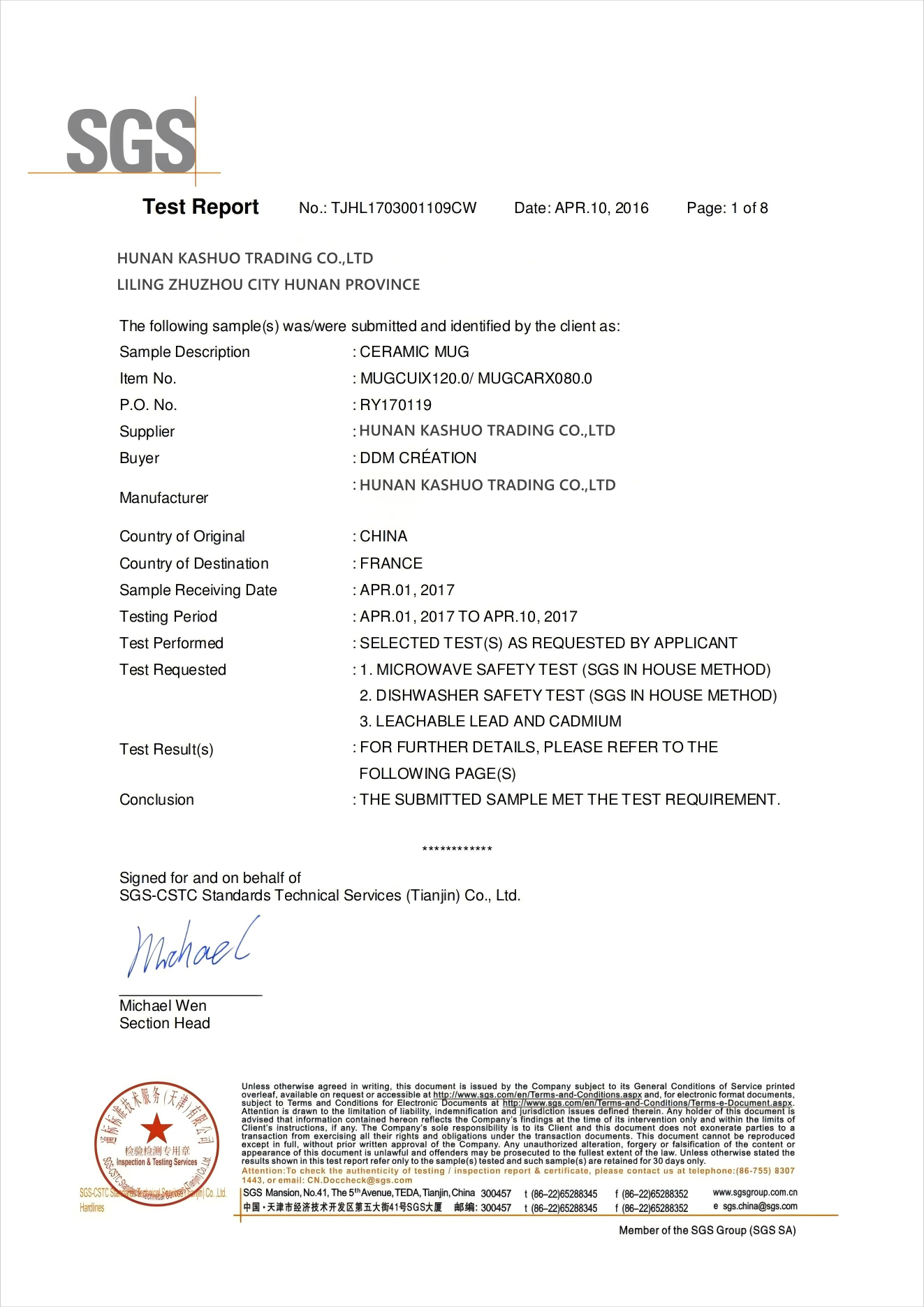

We adhere to the core of "safety, durability and sustainability". All products have passed FDA (USA), LFGB (Germany) and SGS tests, with lead and cadmium dissolution ≤ 0.01mg/L, far exceeding international food contact standards. From cultural IP co-branding to commercial scene customization, from 3D modeling to global logistics delivery, STORIWARE has become a trusted ceramic partner for global customers with "full-link customization capability + international compliance guarantee".